Colorful Reflective Ink - NYF-8010,NYF-8011,NYF8015,etc

| Type: Solvent Based Ink | Printing Type: Screen Printing | Place of Origin: Shanghai China (Mainland) | Brand Name: NYF |

| Model Number: NYF-8010,NYF-8011,NYF8015,etc | Color: Colorful | Appearance: Paste |

Reflective Ink

Features:

NiYaFureflective ink is one of the special ink products developed by our company, is a new type of reflective material. It made of materials by using high brightness reflective powder and high-quality high-tech resin, to prevent ultraviolet light irradiation to prevent color fade peel, highly resistant to salt spray, acid and alkali resistant properties, have easily printed, durable, quick-drying, high-intensity reflective, color durable and so on. Just enough to achieve a layer of reflective effect. The reflective ink can be sprayed, can be painted, can brush, dip brush, can also be easy to operate directly. Products similar products meet international standards, comparable with the automobile paint.

Applications:

NiYaFureflective ink different with reflective film which used on both sides of the road, reflective film can only be used on smooth surface. Such as: aluminum, glass, steel and other surfaces. NiYaFu reflective ink is in addition to the above surface applications, but also can be used for cement concrete, wood and other uneven surfaces, it is widely used in billboards, underground tunnels, bridges both sides of the barricade, the city elevated pillar, the obstacles in the road property alerts, road isolation rotten, rural road safety warning Crossings pile, cement wall, fire facilities, license plate number amplification, fabric which can or not touch the high temperature do reflective printing and more.

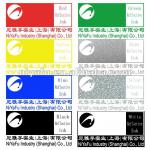

Reflective colors:red, yellow, blue, green, golden, silver, gray, clear, black and white (special colors can be customized).

Construction Description:

1, Printing or construction should be complete removal of the substrate surface before the oil, water stains and dust, while maintaining the working surface is dry.

2, First print normal ink or paint at the bottom (silver gray or the color you want), dry, then print the reflective ink on it. If the primer need baking, it should be baked together with reflective ink.

3, Before printing reflective ink, the ink need to be fully stir. Before add material also stir again; In construction, stirring constantly to prevent the precipitation, which will reduce the reflective effect.

4, Reflective ink coating thickness, color strength in ensuring the case of uniform thin reflective coating made the best, a molding.The film is too thick, a thickness of about 20 microns.Otherwise in effective.

5, The product uses ketone(Such as Cyclohexanone etc.), xylene as a diluent.

Recommended dosage: Ink:Diluent=1:0.2 ~ 0.5.

6, Using screen printing, we recommend using 80 to 120 mesh screen ;When using the spray gun (recommended construction of W-71 type gun), gun from the work surface for about 18 to 20 cm, spray angle 45 ° or so, pressure control at 0.3MPa, spray way up.

7, After the work is printed with thinner spray cleaning tool.

Consumption of paint:According to the printing area, depending on the theoretical value of about 15 square meters / kg

Packaging and storage:This product is packed in tin containers, packaging specifications: 1kg/can(11.5cm*11.5cm*12.5cm), 5kg/pail.Storage to prevent the sun and rain, should be stored in the shade, open flame is prohibited.

Note:The primer of this product should be uniform, not missing. Reflective ink layer should be thin, not thick, otherwise there is no reflective effect.