Heat Transfer Printing Film For Plastic Pail/hot foil stamping

| Material Type: Film | Material: PE,PP,PET,PS,PVC,ABS | Application: Heat Transfer Printing Film For Plastic,Metal,Glass,Wood...etc. | Type: Heat Transfer |

| Temperature: Low | Place of Origin: Zhejiang China (Mainland) | Brand Name: Liyang | Printing Type: Heat transfer printing |

| Colors: Multi-colors, can order at most 10 colors | Plate: Gravure Printing | Glue & Ink: Safe and non-toxic | Certificate: ISO9001:2000,SGS |

Heat Transfer Printing Film For Plastic Pail/hot foil stamping

Heat Transfer Printing Film For Plastic Pail is for kinds of sizes containers printing,the beautiful designs make them more attractive in market.

The film has the advantages of high definition, bright color, fading-resistance, contributing to significantly upgrading of product quality and increasing of commodity added-value. And the products are widely used in surface decoration of plastics ( PP, ABS, PS,PE,PET, PC ),household goods, stationery, cosmetics, electrics and toys etc.

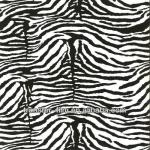

Printing Sample

A. Material: Transparent PET film.

B. Accurate chromatography, good adhesion, high gloss, clear graphics;

C. Production time: Normal film can be finished within 8-10days. The metallic and glitter(laser) film finished within 10-12days. Because it needs more days for making Aluminizing on back of design.

D. Plate size: It will be made according to your design size and numbers.

Our Advantages:

1. All the printing oil is safe and poisons free with international standard;

2. Nine color patterns can be easily finished in one process;

3. Can add high values to the products for vivid patterns and live colors;

4. Strong adhesion and wear resistance after transfer printing, also can increase product value and strengthen market competitive ability;

5. Can withstand the post-processing such as inkjet, sandblasting, the second injection, bending and punching etc.;

6. Widely used on household goods, stationery, cosmetics, electric appliance and toys etc.

Procedure | |

| 1.Artwork | we will make an layout for you ,according to your design & size |

↓ | |

| 2.Confirm the artwork | You Confirm the layout & we will launch your order for plate making |

↓ | |

| 3.Plate making(cylinders) | It takes about4~7 days |

↓ | |

| 4.Print the film | Print in big rolls →drying → cut into small rolls →quality check It takes about 3 days Glitter film needs 5 days more for aluminzing |

↓ | |

| 5.Packaging | Polybag+drying agent+carton |

↓ | |

| 6.Delivery | By sea / by air →up to you |

| Payment | Plate making fee & 30% film pay in advance; 70% pay before delivery. |

Our company with SGS approved, heat transfer film printing ink passed American ASTM F 963-08 & European EN71 & ROHS standard, and heat transfer machine is CE approved. So we are with full confidence to support best products and with steady quality in our cooperation

.

| Packaging Detail:polybag+carton or pallet. (the heat transfer printing film: we will cut them in rolls according to size and meters.Then packed with polybag.About 24 rolls will be packed with one carton.) |

| Delivery Detail:7 days for normal,12 days for laser. |