High Quality Agriculture Use Grass Bale LLDPE Silage Film - silage film 25micx750mmx1500m

| Material: LLDPE,LLDPE with metallocene | Type: Stretch Film | Usage: Agriculture | Feature: Moisture Proof |

| Hardness: Soft | Processing Type: Blow Molding | Transparency: Opaque | Place of Origin: Shandong China (Mainland) |

| Brand Name: zhengdexiang silage film | Model Number: silage film 25micx750mmx1500m | Category: agriculture film-Silage Film | color: black/ green/white |

| thickness: 20-35mic | width: 250mm/375mm/500mm/750mm | length: 1000-1800m | Elongation: 300-600% |

| UV: last 12 months | business type: 11-year experience manufacturer | quality certificate: SGS,MSDS |

High Quality Agriculture Use Grass Bale LLDPE Silage Film

1. About us/ Company Profile

We are the professional manufacturer specializing in LLDPE silage film since 2002.

We have 10 production lines ,which make sure 1000 tons per month.

Our products have passed SGS,BV,MSDS and Japan quality certificate.

We have established a mutually long-term business relationship with customers from Japan, US, New Zealand, Australia, Finland, Norway and so on.

2. About Silage Film

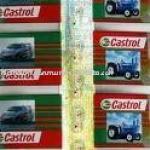

The silage baling film, comes with a 12-month guarantee against UV degradation, features high UV stabilization and provides an airtight and weatherproof shield, when used according to instructions.

It is available in black, green and white. It is wound onto the now familiar environmentally friendly cardboard cores.

3. Usage of Silage Film

The goal of silage making is to conserve and store crop nutrients using lactic acid bacteria to ensure rapid fermentation in air-free conditions and to minimise losses from harvesting until feeding.

Whatever the system, the ensiling and storage system's main functions are to exclude air during the ensiling process and to prevent air from entering the silage during storage.

Speed of harvest, moisture content, chop length, silage distribution and compaction can greatly influence the fermentation process and storage losses.

Efficient fermentation generally ensures a more palatable and digestible feedstuff.

This promotes maximum dry matter consumption by livestock that usually results in improved milk and/or live weight gain performance.

4. Features of Silage Film

1) High tack plus high puncture and tear resistance

2) High load retention (for bale integrity)

3) Guaranteed to withstand the harshest climates

4) Made to International Quality Standards for extreme conditions

5) More bales per roll. Greater wrapping efficiency

6) Provides an airtight and weatherproof shield

7) 12 month guarantee against UV degradation

8) Stretch level at approximately 300%

9) Good thickness distribution in the film at 25 microns optimum

5. Silage Film Popular specifications

Typical Range Of Silage Film | |

| Width (mm) | 250/375/500/750 |

| Length (m) | 1500/1800 |

| Thickness (mic) | 25/28/30 |

| Core ID | 3" Plastic Core/ 3" Paper Core |

| Color | White/Green/Black |

| Packing | In pallets, 1 roll/carton |

6. Silage Film data sheet

| Thickness range | Tensile strengthlongitudinallateral | Elongation at break(longitudinal, lateral) | Angle tear strength(longitudinal, lateral) | Impact ability of pendulum | Tackiness | Light transmission rate | Fog density |

| Um | Mpa≥ | %≥ | N/mm≥ | J≥ | N/cm≥ | %≥ | %≤ |

| 18-19 | 38 | 300, 600 | 120 | 0.15 | 3.0 | 92 | 2.5 |

| 20-25 | 39 | 300, 600 | 120 | 0.46 | 3.0 | 91 | 2.6 |

| 26-35 | 40 | 300, 600 | 120 | 0.19 | 3.0 | 90 | 2.7 |

| 36-50 | 41 | 300, 600 | 120 | 0.21 | 3.0 | 89 | 2.8 |

| Packaging Detail:silage film package terms: 1) 1 roll/ carton 2) 50rolls per pallets 3) 10 pallets,500 rolls in 1x20' container 4) 18 pallets, 900rolls in 1x40' container |

| Delivery Detail:15 days after receiving the deposit |