paper pulp egg tray - FC-ZMG4-32

| Type: Tray | Material: Paper | Use: Egg | Process Type: Pulp Moulding |

| Custom Order: Accept | Place of Origin: Shandong China (Mainland) | Brand Name: FC | Model Number: FC-ZMG4-32 |

| certificate: ISO9001:2008 | Raw Material: Waste Paper,Carton,Newspaper | Output: 2800-3500 pcs/h | Molding Mould/pcs: 32 |

| Transfer Mould/pcs: 4 | drying system: gas,oil,coal,wood | finished product: egg tray,egg box,fruit tray,egg carton |

Environmental Waste Paper Recycling Machine. Egg tray pulp molded production line , Paper products forming moulding machines make egg tray and egg box, egg tray manufacturing machine , Pizza box making machine,recycling paper machine.Eggs tray machinery manufacture

Eggs packing machine low price high output

Product Description:

Customized forming mold,it can forming any kind of shape paper products as you want.

FC series egg tray making machine features of high efficiency, low maintenance and energy saving during the ten year practice. The pulp molding system can use all kinds of waste paper to produce high quality molded fiber products. Such as, egg boxes, apple trays, meat portion trays, vegetable portion trays, fruit portion trays, strawberry punnets , kidney trays, wine packs, can trays, seed cubes,coffee tray,bottle tray seeds tray, ect.

Reciprocating Egg Tray Machine is the machine which can use all kinds of waste paper as the raw material to produce egg tray, egg box, pizza box, industrial tray and other packing products etc. by changing different moulds. It has received good reputation for its good quality, high output, low energy-consuming and low maintenance,environmental protection.

Main Technical Parameters:

| Product Name | Reciprocating Type | ||

| Model | FC-ZMW-2 | FC-ZMW-3 | FC-ZMW-4 |

| Output pcs/hr | 400-600 | 600-800 | 800-1000 |

| Molding Mould/pcs | 2 | 3 | 4 |

| Transfer Mould/pcs | 2 | 3 | 4 |

| Product Name | Reciprocating Type | |||

| Model | FC-ZMW-6 | FC-ZMW-8 | FC-ZMW-10 | FC-ZMW-12 |

| Output pcs/hr | 1000-1200 | 1200-1600 | 1800-2000 | 2200-2400 |

| Molding Mould/pcs | 6 | 8 | 10 | 12 |

| Transfer Mould/pcs | 6 | 8 | 10 | 12 |

| Product name | Roller type | ||

| Model | FC-ZMG3-24 | FC-ZMG4-32 | FC-ZMG6-48 |

| Output pcs/h | 1500-2000 | 2800-3500 | 4800-5000 |

| Molding Mould/pcs | 24 | 32 | 48 |

| Transfer Mould/pcs | 3 | 4 | 6 |

The details of the egg tray machine:

1) The paper pulping system:

Pulping system is mainly comprised of hydrapulpter, pulp pump, multi-function refiner machine, blender, control cabinert,ect.

This process is designed to allow the waste paper turned into pulp.

2) Forming system:This is primarily using the aluminum mold to absorb the pulp then molding the egg tray , by vacuum pump.The blow molding technology is the key.

3) Drying system: We could produce single drying line and multi-layer drying line in according to our customers' request,

The stove or the burner, The coal, gas,diesel oil. According the price the coal,gas,oil.

4) Packing system: It including the stacking system and the counting system.

Packing : standard container

Delivery Detail: within 60 working days after the receipt of down payment.

Automatic stacking and counting machine:

Single Drying system:

Multilayerdrying system:

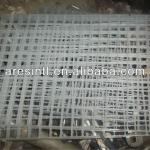

The Forming Mould:

Finished Product: Eggs Box

Finished product: eggs tray,fruit tray,glass bottle tray,coffee tray

| Packaging Detail:Standard export pakage |

| Delivery Detail:Within 60-90 days after received the deposit |