plastic pvc shrink film,beverages bottle label, PVC heat shrink film

| Material: PVC | Type: Shrink Film | Usage: Packaging Film | Hardness: Soft |

| Processing Type: Casting | Transparency: Transparent | Place of Origin: Hubei China (Mainland) | Brand Name: Y.F |

| Payment & Shipping Terms: : Price:: FOB USD 2270~2381 / Metric Ton | Minimum Order Quantity:: 11 Metric Ton/Metric Tons | Port:: Shanghai | Packaging Details:: Standard export packing |

| Delivery Time:: 25 days | Payment Terms:: T/T | Supply Ability:: 100 Metric Ton/Metric Tons per Month |

plastic pvc shrink film,beverages bottle label, PVC heat shrink film

PVC shrink sleeve film is made by cast technology. We can produce pvc shrink film,tubular pvc shrink film,pvc shrink sleeve and cut into small pieces.

The PVC shrink film excellent to machine printing, no wrinkles after printing. High TD shrinkage

Production range of pvc shrink film:

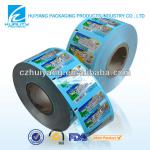

PVC shrink film is a heat sensitive plastic material, it could avoid printing on bottle directly, and pictures are vivid.

Our PVC shrink film is suitable for beverage and food container labels, full body labels, tamper-evident bands and cap seals.

specification :

1).more cost-effective than carton packing

2).convenient to carry and helps to promote sales

3).fantastic transparency, shrink ability and tear resistance

4).adjust and solution on your cost-saving on packing

5).0-10 colors at most with bright,high class and valuable sense

6).match the print process with your graphic needs

7).cling tightly to just about any bottle shape by well-designing

8).specifications can be customized; high quality and competitive

price

9).nontoxic, odor free and environmentally friendly with high strength

10).many styles, competitive quality&price

Advantage

Super transparency

Excellent shrinkability

Highly impact resistant

Highly water resistant

Excellent printability

Ultra-violet barrier

Excellent printability

Technical data sheet of PVC shrink film

ITEMS | VALUE | STANDARD | REMARKS | ||

Density | 1.38-1.40g/cm3 | GB/T 6672 | —— | ||

Roll Width | 100.00~960.00±3.00mm | QB/T 3632 | —— | ||

Thickness | 1. Thickness≤0.05mm Average thickness Tolerance:+/-0.002mm Absolute thickness:≤0.010mm among ten check points 2.Thickness≥0.05mm Average thickness Tolerance:+/-0.003mm Absolute thickness:≤0.012mm among ten check points | GB/T 6672 | Check 20 dots(horizontal) use a micrometer | ||

| Shrinkage property | MD | 0%≤MD≤5% | QB/T 3632 | 100°C,1min,in water | |

| TD | 46%≤TD≤52% | 100°C,1min,in water | |||

| Tensile strength | MD | ≥42.0Mpa | GB/T 1040 | Test speed 100mm/min, gauge Length 25mm | |

| TD | ≥50.0Mpa | ||||

| Elongation at break | MD | ≥70% | GB/T 1040 | ||

| TD | ≥50% | ||||

Surface | Transparent and bright. No apparent mist, air bubble, dot, impurity, strip and abrasion | QB/T 3632 | Keep the film facing the light, Remain parallel the eyes and the film | ||

Smooth | The surface of the film should be smooth and without apparent pleat,floucing and drop edge | QB/T 3632 | Get 4 meters film, straighten both ends | ||

Beeline | The double sides of the film should be in line, no apparent curve. To test the 4 meters film, folioing the film, the tolerance of the double edges should be less than 2cm | QB/T 3632 | —— | ||

No. of joints | No more than 2 joints per roll. Joint spacing no less than 300 meters | QB/T 3632 | Double sides of joints stick with tape | ||

The others | Negotiation | —— | —— | ||

Storage conditions: Shrink films are sensitive to high temperatures.We recommend storing in original packaging at room temperature below 25°C not directly exposed tosunlight and humidity. Layflat quality may deteriorate after long storage Dependent on film type, roll length and storage conditions. Usage within a period 3 months after the indicate production date is recommend. | |||||

Test conclusion | QC PASSED | ||||

Remark | HUBEI Y.F PACKAGING MATERIALS | ||||

Payment term

(1) Sample : 100% by WESTERN UNION or by Bank Account

(2) Main order: 30% of the total value should be paid as deposit by T/T before production, and the balance should be paid before shiping also by T/T.

Samples in colors and transparent

Application :

Delivery time

About 20 days after receiving the deposit

Way of packing

(1) upright Pallet packing

(2) Suspended packing

About our factory :

| Packaging Detail:standard export packing |

| Delivery Detail:About 20 days after receiving the deposit |