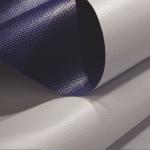

plastic silage wrap/white plastic silage wrap/green plastic silage wrap/black plastic silage wrap - plastic silage wrap-25micx750mmx1500m

| Material: LLDPE | Type: Stretch Film | Usage: Agriculture,plastic Silage wrap for agriculture bale wrapping | Feature: Moisture Proof |

| Hardness: Soft | Processing Type: Blow Molding | Transparency: Opaque,opaque | Place of Origin: Shandong China (Mainland) |

| Brand Name: zhengdexiang plastic silage wrap | Model Number: plastic silage wrap-25micx750mmx1500m | Category: agriculture film | thickness: 20mic-30mic |

| width: 250mm or 375mm 500mm or 750mm | length: 1500m or 1800m | Elongation: 300-600% | Core Inner Diameter: 3inch/76mm |

| orginal place: Qindao,China | Business type: 10-year experience manufacturer |

Plastic Silage Wrap Manufacturer

1. About us/ Company Profile

We are the professional manufacturer specializing in PE plastic silage wrap since 2002.

We have 10 production lines ,which make sure 1000 tons per month.

Our products have passed SGS,BV,MSDS and Japan quality certificate.

We have established a mutually long-term business relationship with customers from Japan, US, New Zealand, Australia, Finland, Norway and so on.

2. About plastic Silage wrap

The silage baling film, comes with a 12-month guarantee against UV degradation, features high UV stabilization and provides an airtight and weatherproof shield, when used according to instructions.

It is available in black, green and white. It is wound onto the now familiar environmentally friendly cardboard cores.

3. Features of plastic Silage wrap

1) High tack plus high puncture and tear resistance

2) High load retention (for bale integrity)

3) Guaranteed to withstand the harshest climates

4) Made to International Quality Standards for extreme conditions

5) More bales per roll. Greater wrapping efficiency

6) Provides an airtight and weatherproof shield

7) 12 month guarantee against UV degradation

8) Stretch level at approximately 300%

9) Good thickness distribution in the film at 25 microns optimum

4. PlasticSilage Wrap Instructions

1)Do not overstretch the film,ensuring the maximum stretch rate is not exceeded.

2)Apply a minimum of 4 layers at 50% overlap

3)Inspect the bales regularly and repair any holes or other damage immediately with an approved repair tape.

4) Store wrapped bales on ends only

5) Do not roll the wrapped bales as damage may occur

6)Ensure no chemicals come into contact with the films as this will cause premature breakdown

7)Use only approved baling twine.

8) Prevent roll damage as this will cause the film to break when wrapping

9) Keep livestock away from wrapped bales

10)Store bales clear of vegetation that can damage the film

11) Inspect and repair any damage caused by rodents or other animals.

12)Store unused film in a cool,dark and dry area.

13This film will last for a minimum period of 12 months from time of wrapping when used in accordance with the above instructions.

14)Take care handling this product as the weight exceeds 20kgs.

5. Plastic Silage Wrap Popular specifications

6. Plastic silage wrap technical information

| Thickness Range | Tensile strength (longitudinal, lateral) | Elongation at break (longitudinal, lateral) | Angle tear strength (longitudinal, lateral) | Impact ability of pendulum | Tackiness | Light transmission rate | Fog density |

| Um≥ | Mpa≥ | %≥ | N/mm≥ | J≥ | N/cm≥ | %≥ | %≤ |

| 18-19 | 38 | 300,600 | 120 | 0.15 | 3.0 | 92 | 2.5 |

| 20-25 | 39 | 300,600 | 120 | 0.46 | 3.0 | 91 | 2.6 |

| 26-35 | 40 | 300,600 | 120 | 0.19 | 3.0 | 90 | 2.7 |

| 36-50 | 41 | 300,600 | 120 | 0.21 | 3.0 | 89 | 2.8 |

| Packaging Detail:Plastic silage wrap package terms: 1) 1 rolls/ carton,50or 56carton per pallets, 2) 500rolls or 560 rolls per 20' container 3) 900 rolls or 1120 rolls per 40' container |

| Delivery Detail:10-15 days after receiving the deposit |