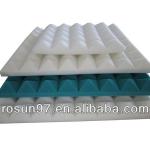

pu foam - 15

| Material: PU | Type: Foam | Place of Origin: Shandong China (Mainland) | Brand Name: ROSUN |

| Model Number: 15 | COLOR: WHITE,GREEN |

polyurethane foam/pu foam/foam mattress

1.anti-freezing,

2.anti-moisture,

3.noise-resistant

polyurethane foam/pu foam/pu foam sheet

1, factory direct sell, professional manufacturer

2, soft, good touch feeling, comfortable

3, samples are free by demand

4,shapes by demand

5,size by demand

6,density by demand

7, colors by demand.

8, adhesive can be provided.

9, with fire retardant material.

10, sound absorbing shape can be provided.

11, widely used in car industry, electronic industry, machinery, pet pads, mattress, cushions, funturers, insoles, etc

Polyurethane foamis created in a basic chemical reaction of a Polyol and Isocyanate, and the final product is determined by the addition of other chemicals but also by the actual polyol type determines the 2 basic family

types.

Typical Applications:

- Water Filters

- Pond Pump Filters

- Tertiary Sewage Tank Filters

- Heat & Moisture Exchange Filters

- Cosmetic Foams

- Air Filters

- Ink Reservoirs

- Pre-Cursor’s for Ceramic or Metal Filters

- Many More

- Fire-blockers for seating applications in aircraft

Typical Uses:

- Gaskets and Seals.

- Shoe Insoles & Orthotic Devices

- Sound absorbers for small communications devices

- Prosthetic Padding

- Shock Absorbers

Property Value Metric (Imperial) Test Method

Density (Core)29 kg/m3 (1.8 lb/ft3) ASTM D1622

Compressive Strength186 kPa (27.0 psi) ASTM D1621

Tensile Strength241 kPa (35.0 psi) ASTM D1623

Open Cell Content8.0% ASTM D2856

Water Absorption1.2 % by volume ASTM D2842

Water Vapour Permeance

50mm sample42 ng/Pa·s·m2 (0.70 Perms) ASTM E96

Dimensional Stability

Volume Change (%) after 28 days

-0.0 @ -20°C (-29°F)

1.5 @ 70°C (158°F) @ 97± 3% RH

0.4 @ 80°C (176°F)

ASTM D2126

Flame Spread Classification**Flame Spread <500

Smoke Developed <500

CAN/ULC-S102

Including S127

Time to Occupancy***24 Hours CAN/ULC-S774

Initial Thermal Resistance (50 mm)RSI: 2.45 m2·K/W (R: 13.9 ft2·hr·°F / BTU) ASTM C518

Hot-Surface PerformancePassed when exposed to 93°C for 96 hours ASTM C 411

Fungi ResistanceAfter 28 day incubation - no fungal growth exhibited ASTM C1338

| Packaging Detail:bag in roll |

| Delivery Detail:prompt shipment |